A machine designed to save time and reduce the cost of collecting, transporting and loading bales when picking up bales from the field. The proposed solution allows for grouping bales behind the baler simultaneously, two next to each other. Thanks to this, when transporting bales from the field, two bales are loaded at once, reducing the time of operation and optimizing fuel costs.

The solution is compatible with various brands of presses available on the market. High-quality workmanship and solid construction ensure trouble-free use. To ensure the continuity of field work and prevent downtime, commonly available parts were used, and the design solutions enable easy and independent replacement.

The truck works automatically and does not require the operator’s intervention. The control is carried out by a high-quality controller from IFM, a leading manufacturer of controllers for agricultural machinery. The trolley has a control panel with a display located in the tractor cabin, which visualizes the loading status, simplifying its operation. The machine is characterized by modern design and simple and reliable solutions.

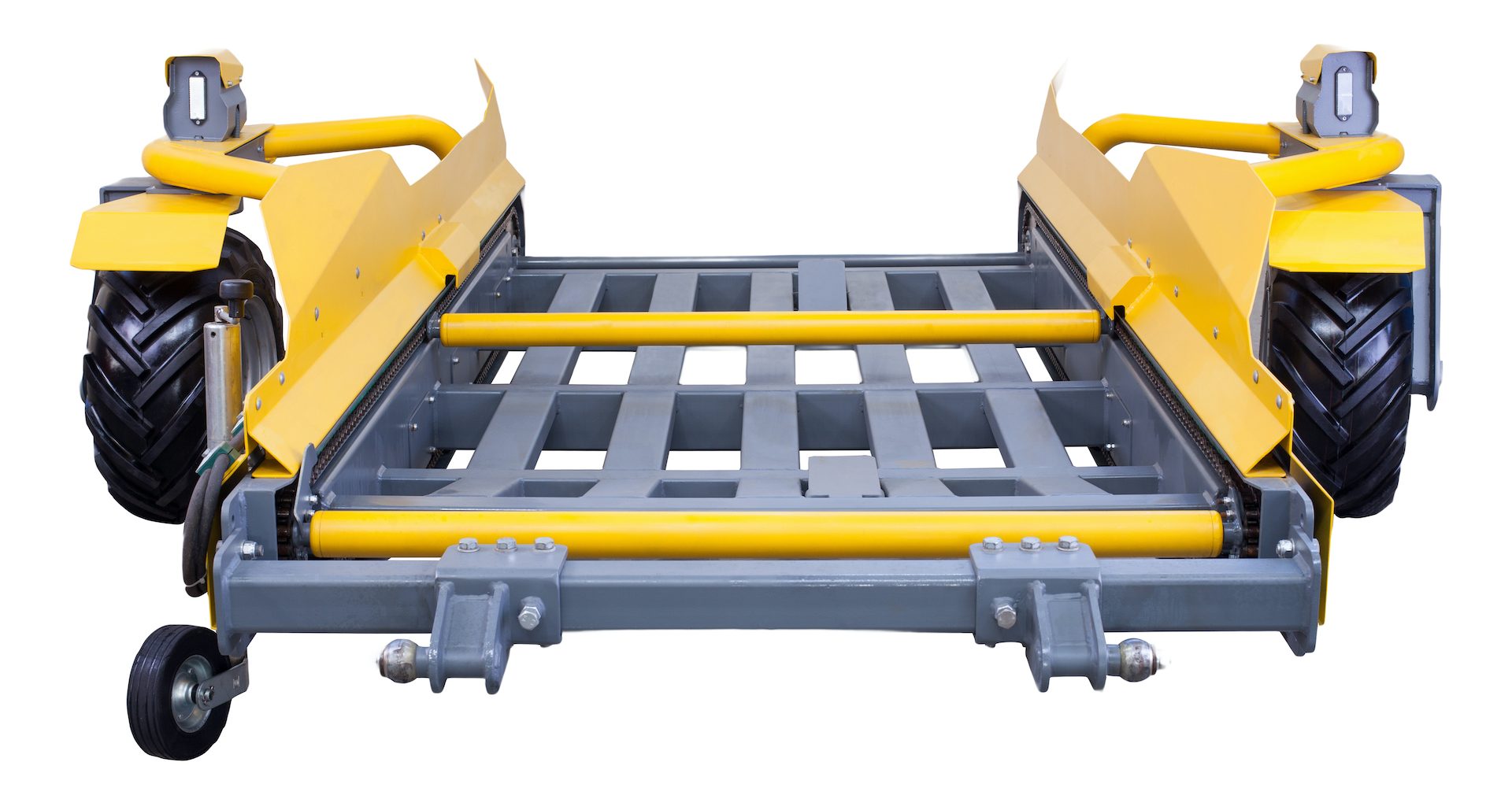

The distinguishing feature is, among others, a previously unprecedented stylistic line, inspired by the wings of an airplane. The shape and perpendicular bends of the sheet give it a unique character. Wide tires and designed fenders make it easier to work in wet terrain. The dimensions of the machine and its marking ensure easy and safe movement on public roads.

TECHNICAL DATA

3546 mm

Length

2880 mm

Width

680 kg

Weight

1800 kg

Payload

Bales with a diameter of 750 mm to 1800 mm

Lighting for driving on public roads

WHAT MAKES US STAND OUT

- Innovation

A new solution for grouping bales behind the baler at the same time, two bales next to each other, thanks to which we load two bales at a time during one driveway. Compatible with various brands of presses

Modern design inspired by the wings of an airplane, based on the bending of the sheets increasing their durability.

- Modern design

- Solid and durable

Solid materials and thoughtful design ensure durability and reliability of the structure. High-quality workmanship, wide tires facilitate work in wetlands, and the fenders protect against dirt.

Stacking the bales in two behind the baler reduces the number of driving up and picking up operations on the field. Thanks to this, we increase the efficiency of a single operation and increase the effi ciency of the operator’s working day. This directly translates into a reduction in fuel consumption, components of the loader or tractor drive system (clutches, brakes) and acceleration of work.

- Time and cost savings

- Simple and reliable

Optimal design solutions, dimensions and markings ensure safe movement on public roads. High-class components translate into reliability.

Adapted to work with various round balers.

- Tested and universal

- Availability of spare parts

The consumable parts are generally available components, thanks to which we avoid unnecessary downtime at work.