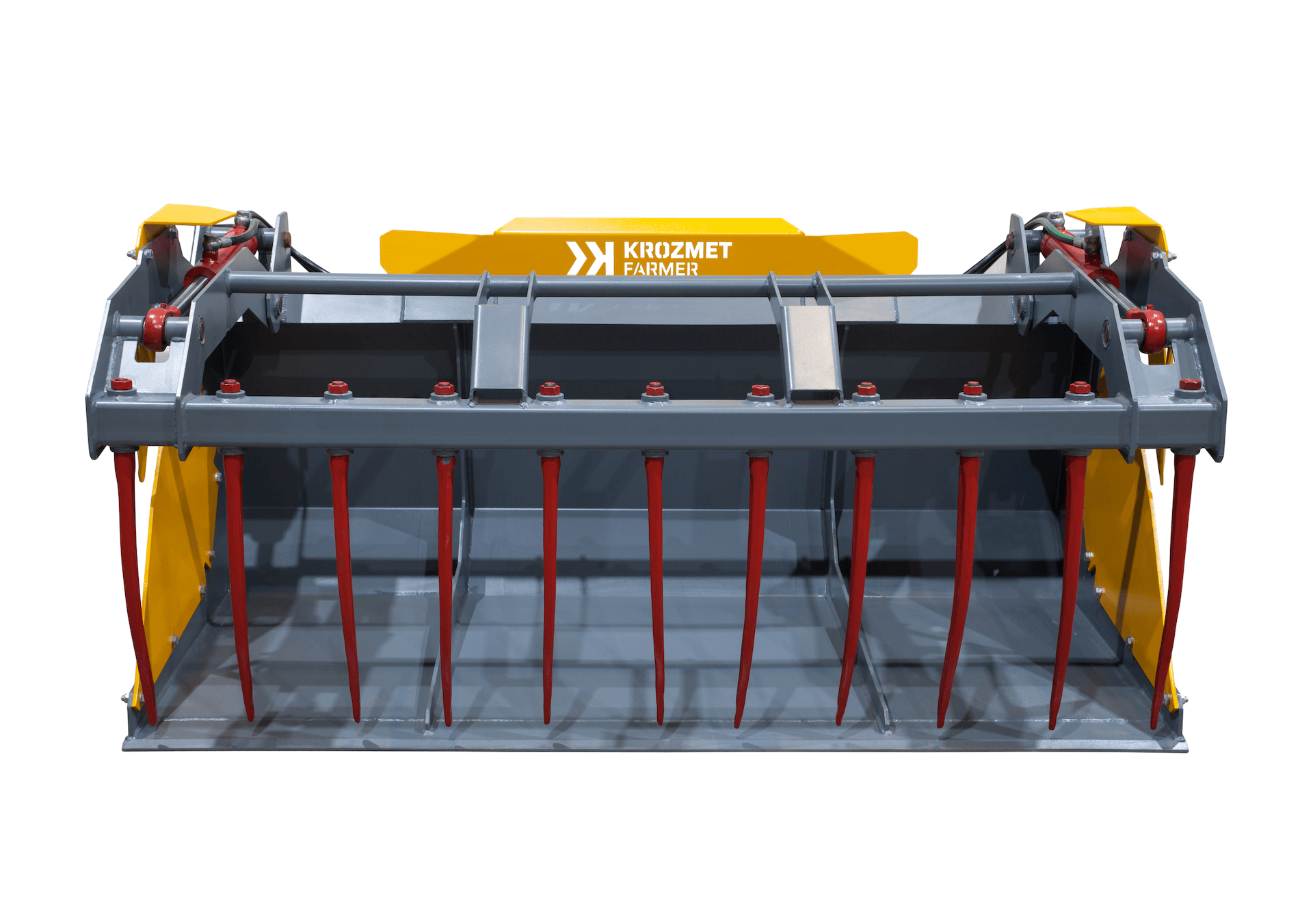

It is a high-quality product, solidly made and ensuring good work results. Strong materials were used for its construction, and the elements of the structure were strengthened internally and externally. As a result, a higher stiff ness was achieved when working in diffi cult conditions. The blade was made of HARDOX HB 500 wear plate. Additional slides were used to increase the durability of the device.

The designed geometry of the structure allows maximum access to the wall itself, also in the open position, and breaking the upper arm increases the loading volume. The compacted spacing of the forged teeth enables the transfer of fi ner materials. The bucket is additionally equipped with side teeth to keep the material within the bucket and prevent the material from falling out. By applying the local bends of the sheets, their stiff ness and strength were increased.

Slightly parted side walls increase the load capacity, and the designed possibility of their disassembly facilitates picking up the material, e.g. from a pile of haylage. In the normal system, they allow you to work with finer materials or slightly more fluid mixtures.

The construction uses actuators and flexible hoses available on the market. This allows for quick and independent replacement without unnecessary downtime at work. The hydraulic quick couplers guarantee easy connection. The two strong actuators applied are hidden between massive elements of the structure, thanks to which their hydraulic connections are well protected against damage, ensuring a long service life of the tool. The absence of protruding parts guarantees easy maintenance.

TECHNICAL DATA

2000 mm

Working width

465 kg

Weight

1200 kg

Load capacity

1,4 m3

Volume

shovel-crocodile

0,8 m3

Volume

scoop

WHAT MAKES US STAND OUT

- Modern design

Modern design inspired by the wings of an airplane. The geometry ensures maximum access to the wall in the open position.

Made of solid materials that increase durability. The blade is made of HARDOX HB 500 wear plate and additional slides are used. Internally and externally reinforced structure provides rigidity for work in difficult conditions. Two powerful hydraulic cylinders ensure a firm grip of the materials to be conveyed. Due to the structure based on the bending of the sheet, a higher bending strength of the side fangs was obtained.

- Solid and durable

- Time and cost savings

Breaking the upper arm increases the loading volume. More compact tooth spacing enables the transfer of loose materials and reduces the unit load per tooth, increasing their durability. The side teeth prevent the material from falling out.

A simple and reliable solution, the hydraulic quick couplings allow for quick and easy connection

- Simple and reliable

- Tested and universal

Slightly tilted side walls, increasing the load capacity, are dismantled to make it easier to pick up material, e.g. from a haylage pile. They allow you to work with finer materials or slightly more fluid mixtures. The device is designed to work with front loaders and loaders. The Euroram connection point has been additionally reinforced to increase the strength of the fastening.

All consumables are generally available, ensuring easy and quick independent replacement without unnecessary downtime at work.